Introduction

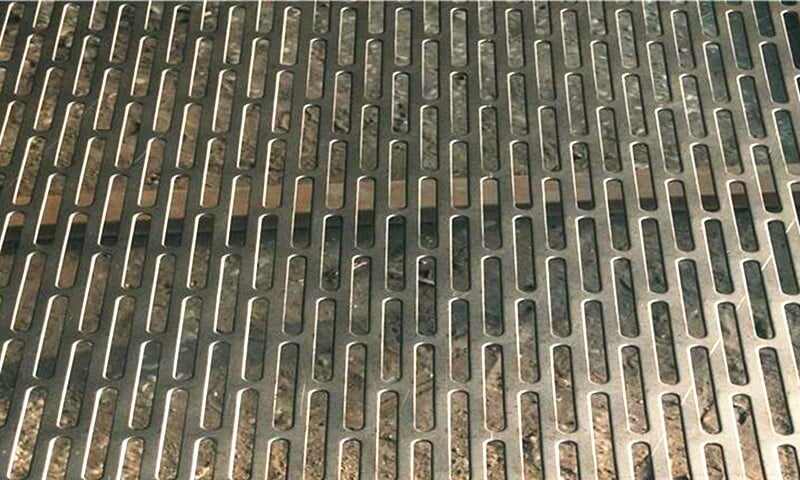

Perforated aluminum sheets are essential materials in modern industry due to their lightweight nature, excellent corrosion resistance, and high strength-to-weight ratio. Particularly in industries such as aerospace, automotive, and construction, perforated aluminum sheets are gradually replacing traditional materials thanks to their lightweight advantages. This article will explore the material properties and lightweight benefits of perforated aluminum sheets, helping you better understand how this metal plate can improve the efficiency and quality of industrial production.

Material Properties of Perforated Aluminum Sheets

The material properties of perforated aluminum sheets make them an ideal choice for many industrial applications. Here are some of the key features of aluminum:

- Corrosion Resistance: Aluminum metal has excellent resistance to oxidation, which helps maintain good performance in harsh and corrosive environments. Perforated aluminum sheets are especially suitable for chemical processing equipment, external buildings, and other applications exposed to harsh conditions.

- Strength-to-Weight Ratio: Aluminum has a low density but relatively high strength, which means that perforated aluminum sheets maintain excellent mechanical strength while significantly reducing overall weight. This property is particularly important in industries such as aerospace and transportation.

- Thermal and Electrical Conductivity: Aluminum has good thermal and electrical conductivity, making it an ideal material for heat dissipation and electrical conduction. Perforated aluminum sheets effectively dissipate heat and prevent overheating, ensuring the stable operation of equipment.

- Workability: Aluminum is easy to process, allowing for the production of different shapes and hole patterns as needed. Perforated aluminum sheets can easily accommodate various custom requirements for specifications, sizes, hole diameters, and perforation rates, meeting the diverse needs of industrial production.

Lightweight Advantages of Perforated Aluminum Sheets

In many industrial fields, lightweight materials are crucial for improving efficiency and reducing costs. Perforated aluminum sheets offer the following lightweight advantages:

- Weight Reduction: The low density of aluminum is one of its greatest advantages. Compared to traditional materials like steel, perforated aluminum sheets are much lighter, significantly reducing the overall weight of products. This property makes aluminum perforated metal sheets more convenient for transport, installation, and use, saving substantial costs in logistics and operations.

- Improved Efficiency: The lightweight nature of aluminum perforated sheets not only helps to lower material costs but also improves overall efficiency during use. For instance, in the automotive industry, lightweight materials help increase fuel efficiency; in aerospace, reducing the weight of aircraft leads to lower fuel consumption and increased range.

- Applicable Industries: Perforated aluminum sheets are widely used in industries that require weight reduction, especially in aerospace, automotive, construction, and other heavy industries. Perforated aluminum sheets provide an ideal lightweight solution for many applications.

Advantages of Customizing Perforated Aluminum Sheets

We offer flexible customization services to ensure that each perforated aluminum sheet perfectly fits various industrial needs:

- Flexible Customization: Based on customer requirements, we provide perforated aluminum sheets in different thicknesses, hole patterns, hole diameters, and perforation rates. Whether it’s high-strength requirements, corrosion resistance, or unique aesthetic designs, we can offer tailored solutions.

- Small and Large Batch Production: Whether you need a small custom order or a large-scale production run, we can handle orders flexibly and ensure timely delivery.

- High Adaptability: Perforated aluminum sheets are highly adaptable and can be used in various fields. From exterior cladding in construction to ventilation systems in industrial equipment, they serve multiple purposes across different industries.

Applications of Perforated Aluminum Sheets

Perforated aluminum sheets have a wide range of applications. Here are some of the key fields:

- Industrial Applications: Perforated aluminum sheets are commonly used in industrial facilities, particularly in environments where ventilation, soundproofing, or protection is required. Whether used for equipment protection or as ventilation and heat dissipation materials, perforated aluminum sheets are an ideal choice.

- Special Requirements: In some specialized projects, perforated aluminum sheets meet specific needs such as high strength, corrosion resistance, and other unique demands. Their customization allows them to perfectly adapt to various complex applications.

Conclusion

Perforated aluminum sheets, with their lightweight, corrosion-resistant properties, and high strength-to-weight ratio, have become indispensable in various industrial fields. From aerospace to construction and automotive industries, perforated aluminum sheets offer undeniable benefits. The perforated aluminum sheets we provide can be customized according to your needs to meet the specific requirements of different projects.

If you are looking for high-performance perforated aluminum sheets, feel free to contact us for more information and to receive a customized solution.