When it comes to galvanized perforated metal sheet, buyers are often concerned about three essential aspects: coating, specifications, and weather resistance. In this guide, we will explain how these factors influence the performance of galvanized perforated metal sheets and help you select the right option for your project.

Why Choose Galvanized Perforated Metal Sheets?

Galvanized perforated metal sheets are widely used in construction, filtration, screening, safety guards, ventilation, and decorative applications. The main advantage of galvanization lies in its ability to protect steel from rust and extend service life.

Compared with carbon steel perforated metal sheet, galvanized options offer enhanced corrosion protection while still maintaining structural strength.

2. Understanding Galvanization: Coating Types

The type of coating directly impacts the durability of a galvanized perforated metal sheet. The most common coating processes include:

- Hot-dip galvanization: Creates a thick, uniform zinc layer, suitable for outdoor and long-term applications.

- Electro-galvanization: Provides a smoother surface and aesthetic finish, but thinner zinc coating compared to hot-dip.

- Zinc-aluminum coating: Enhances corrosion resistance in aggressive environments.

If your project requires long-lasting protection in outdoor or marine environments, hot-dip galvanization is highly recommended.

3. Key Specifications to Consider

When buying galvanized perforated metal sheets, specifications vary depending on usage. You should consider:

- Material thickness: Typically ranges from 0.3 mm to 10 mm. Thicker sheets provide greater strength, while thinner ones are easier to bend and shape.

- Hole shape and size: Options include round holes, square holes, hexagonal holes, and slotted holes. For example, a round hole perforated metal sheet is common in filtration, while a slotted hole perforated sheet is often used in soundproofing and ventilation.

- Sheet dimensions: Standard size is usually 1m x 2m, but customization is available.

- Open area ratio: The percentage of hole area compared to total sheet area, affecting ventilation and strength.

4. Weather Resistance Comparison

One of the most critical factors in choosing a galvanized perforated metal sheet is weather resistance.

- Mild environments: Electro-galvanized sheets are sufficient for indoor use.

- Moderate outdoor exposure: Hot-dip galvanized perforated sheets provide superior performance.

- Harsh or coastal environments: Zinc-aluminum coated perforated sheets deliver the best corrosion resistance.

Compared with stainless steel perforated metal sheet (internal link), galvanized sheets offer a more cost-effective solution while still achieving high levels of protection against rust.

5. Practical Applications

Galvanized perforated metal sheets are applied in:

- Building façades and cladding

- Ventilation grilles and air diffusers

- Safety guards for machinery

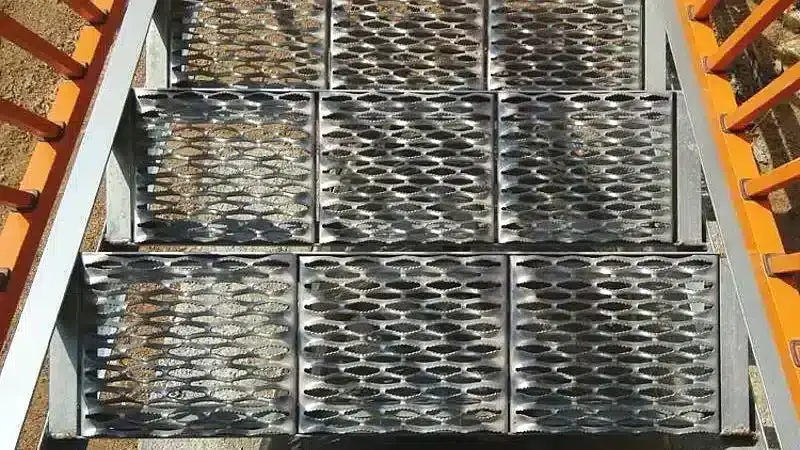

- Stair treads and anti-slip flooring

- Acoustic panels and soundproofing materials

6. How to Choose the Right Galvanized Perforated Metal Sheet

To make the best purchase decision, consider the following checklist:

- Define the application: Indoor, outdoor, decorative, or structural.

- Select coating type: Hot-dip for durability, electro-galvanized for aesthetics, zinc-aluminum for extreme environments.

- Match specifications: Choose hole pattern, thickness, and open area ratio according to functional requirements.

- Consider long-term cost: While hot-dip galvanized perforated metal sheets may cost more upfront, their extended service life often results in lower long-term expenses.

A galvanized perforated metal sheet is an excellent choice for projects that demand strength, durability, and corrosion resistance. By carefully comparing coating types, specifications, and weather resistance, you can ensure the sheet you select performs reliably in your specific application.

For more options, you may also explore our aluminum perforated metal sheet and high manganese steel perforated sheet to compare different materials.