Introduction

In heavy-duty industries such as mining, screening, and mechanical engineering, materials that can withstand extreme impact and abrasion are essential. Among the many types of perforated metal sheets, the High Manganese Steel Perforated Metal Sheet stands out due to its exceptional strength, hardness, and wear resistance. This type of perforated metal combines high toughness with a unique work-hardening property, making it ideal for demanding industrial environments.

Material Composition and Structure

High manganese steel, often known as Hadfield steel, typically contains 10%–14% manganese and a significant amount of carbon. This composition provides a rare balance between ductility and hardness. When subjected to strong impact or pressure, the surface of the metal becomes even harder, while the inner core remains tough and flexible.

This self-hardening characteristic gives high manganese steel perforated sheets a major advantage over traditional carbon steel or galvanized steel alternatives. The result is a material that resists wear and deformation, even in environments where continuous friction or heavy material flow occurs.

Key Advantages

- Superior Wear Resistance

The surface hardens under impact, providing a protective layer that dramatically extends service life. - High Strength and Impact Absorption

It maintains structural integrity even under high stress, preventing cracking or tearing. - Work-Hardening Ability

Unlike conventional metals that weaken over time, high manganese steel becomes stronger the more it’s used. - Cost Efficiency

Longer lifespan means reduced downtime, maintenance, and replacement costs. - Versatile Customization

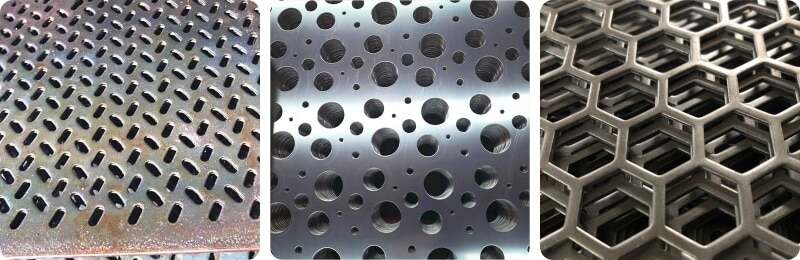

Available in multiple thicknesses, hole sizes, and perforation patterns depending on specific industrial requirements.

Industrial Applications

The High Manganese Steel Perforated Metal Sheet is mainly used in areas where durability and performance are critical. Common applications include:

- Mining and quarrying: for screening, sorting, and crushing materials.

- Heavy machinery and mechanical protection: used as protective covers and anti-wear components.

- Construction and transportation: applied in vibration-resistant structures and wear-prone parts.

- Industrial filtration: ideal for separating solid materials under abrasive conditions.

In mining operations, for instance, screens made from high manganese steel perforated sheets significantly outperform those made from mild or galvanized steel. They can handle repeated impact from rocks and ores without losing shape or strength.

Comparison with Other Metal Sheets

While stainless steel perforated metal sheets are known for their corrosion resistance and aluminum perforated sheets for their lightweight nature, high manganese steel perforated sheets dominate in environments requiring extreme wear and impact resistance.

For users who require corrosion protection combined with cost-effectiveness, galvanized perforated metal sheets are another reliable option, particularly in moderate industrial settings. However, for heavy-duty applications like ore screening, conveyor protection, or mechanical guards, the high manganese steel type remains the superior choice.

For more information on custom-made industrial-grade perforated metals, you can explore our custom perforated metal sheets from Chinese factories, tailored to meet unique material and size specifications.

Customization and Manufacturing at Senchi Metal

At Anping Senchi Metal Wire Mesh Products Co., Ltd., we specialize in manufacturing custom perforated metal sheets to meet diverse industrial needs. Our factory in Anping County, Hebei Province, China, is equipped with advanced machinery that allows flexible customization of:

- Hole shapes (round, slot, square, hexagonal, etc.)

- Plate thickness

- Material type

- Open area percentage

- Surface treatments

Whether you need a high manganese steel perforated plate for mining or a carbon steel perforated metal sheet for mechanical processing, we offer both small-batch and bulk production to ensure quality and delivery efficiency.

Conclusion

In summary, the High Manganese Steel Perforated Metal Sheet offers outstanding wear resistance, high strength, and long-term performance in demanding industrial conditions. Its unique work-hardening property ensures that it not only withstands heavy impact but also becomes tougher with continued use.

For industries looking for reliable materials that reduce downtime and extend equipment life, high manganese steel perforated sheets provide an unmatched combination of durability, customization, and cost efficiency.