In today’s industrial manufacturing, micro perforated metal sheets play a crucial role in applications requiring precise airflow, acoustic control, and fine filtration.

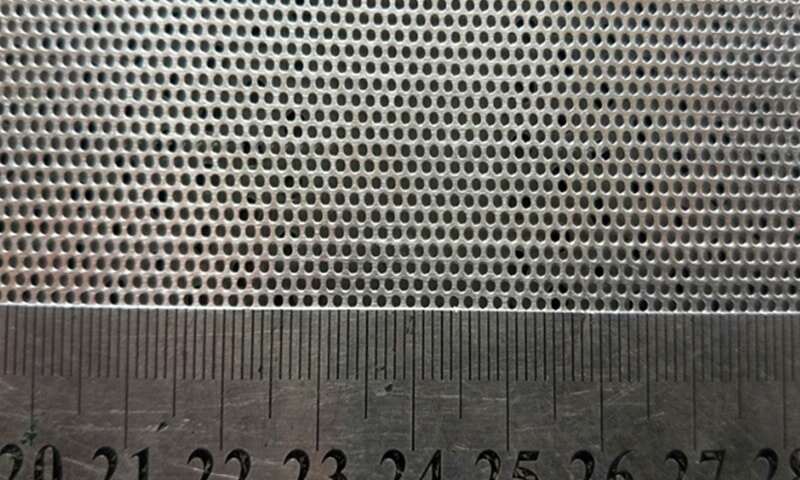

Unlike standard perforated sheets, micro perforated types feature extremely small holes—usually less than 2 mm in diameter—which create a unique combination of strength, durability, and performance.

These sheets are widely used in machinery enclosures, ventilation systems, automotive parts, and other engineering environments where sound reduction and air passage efficiency are essential.

1. What Is a Micro Perforated Metal Sheet?

A micro perforated metal sheet is a thin metal panel containing thousands of uniformly spaced micro-holes, precisely formed using CNC punching or laser perforation technology.

This high-precision process ensures consistent hole quality, which is critical for acoustic absorption and filtration applications.

Compared with conventional round hole perforated metal sheets , micro perforated designs feature much smaller apertures, offering enhanced acoustic and filtration performance.

They are available in various metals including stainless steel, aluminum, galvanized steel, and carbon steel—each chosen according to the application environment and mechanical requirements.

2. Common Materials and Thickness Options

Our factory produces micro perforated metal sheets using multiple materials to suit different industries:

- Stainless Steel (304, 316L): Exceptional corrosion resistance for chemical and marine environments.

- Aluminum: Lightweight and non-corrosive, perfect for HVAC and acoustic panel systems.

- Galvanized Steel: Combines strength with rust prevention for long-term outdoor use.

- Carbon Steel: Heavy-duty option for structural and mechanical protection.

Typical thickness ranges from 0.3 mm to 3 mm, depending on hole diameter and sheet size.

Each sheet can be customized with specific tolerances, open area ratios, and finishing treatments such as powder coating, anodizing, or galvanizing.

3. Hole Patterns and Perforation Sizes

The hole pattern defines both the function and aesthetics of a micro perforated sheet.

Common perforation types include:

- Round Holes: The most popular design for uniform airflow and sound absorption.

- Square Holes: Provide strong mechanical support and controlled flow rate.

- Hexagonal Holes: Offer a higher open area percentage for efficient filtration.

Standard perforation diameters range from 0.5 mm to 2 mm, but fully customized designs are available upon request.

Patterns can be staggered or straight, depending on performance needs.

Special shapes such as slot, oblong, or cross holes can also be produced for specific engineering purposes.

4. Manufacturing Process & Customization Capability

Each micro perforated metal sheet is manufactured using advanced precision equipment, ensuring consistency and quality at every stage.

Production process includes:

- Raw material selection and preparation

- CNC or laser perforation

- Deburring and surface finishing

- Optional coating or anodizing

- Quality inspection and packaging

Our factory supports both small-batch customization and mass production, making it easier for clients to test prototypes or fulfill large industrial orders.

Every order can be tailored by adjusting the hole size, pitch, sheet thickness, and material type according to customer drawings or specifications.

5. Industrial Applications of Micro Perforated Metal Sheets

Micro perforated metal sheets are widely adopted in engineering and industrial environments due to their fine perforation accuracy and mechanical stability.

Common applications include:

- Noise Reduction Panels: Used in factories, power plants, and compressor housings.

- Filtration Systems: Ideal for dust collection, ventilation ducts, and liquid filtration.

- Automotive Parts: Lightweight panels for engine noise reduction or airflow control.

- Electronic Enclosures: Allow heat dissipation while maintaining protection.

- Machinery Safety Covers: Prevent direct contact with moving parts while maintaining visibility and ventilation.

These advantages make micro perforated metal sheets a superior alternative to woven wire mesh or expanded metal in many industrial settings.

6. Why Choose Our Factory

As a professional manufacturer of perforated metal sheets in China, we focus on high-precision production and customization flexibility.

We can produce micro perforated sheets in different sizes, materials, thicknesses, and perforation types—meeting diverse industrial requirements.

Our advantages include:

- Support for one-piece minimum order quantity

- Fast delivery and reliable quality control

- Custom engineering support for special applications

- Competitive pricing directly from factory source

With advanced CNC perforation technology and a skilled production team, we’ve supplied micro perforated solutions to industries across Europe, America, and the Middle East.

For product inquiries or technical assistance, please contact us at info@perfsheet.com.

Conclusion

A micro perforated metal sheet is more than just a finely punched panel—it is an engineered material designed for performance, durability, and precision.

Whether your application involves sound control, ventilation, or filtration, choosing a reliable and customizable manufacturer ensures consistent quality and long-term value.

Our factory remains committed to providing tailored solutions that enhance efficiency and performance in every industrial project.