In industrial applications, the open area of a perforated metal sheet directly affects its performance in terms of airflow, light passage, and structural integrity. For engineers, fabricators, and design teams, understanding how to calculate the open area of a rectangular perforated metal sheet is critical for achieving the right balance between strength and efficiency.

Rectangular perforations are widely used in filtration systems, acoustic enclosures, ventilation panels, and machinery protection covers, where a specific flow rate or visual transparency is required. Compared with decorative perforations, rectangular holes emphasize functionality, durability, and precision—making them a preferred choice for industrial environments.

What Is Open Area and Why It Matters

The term open area refers to the percentage of the sheet surface that consists of holes. A higher open area allows for better airflow and drainage but reduces material strength. Conversely, a lower open area enhances rigidity but limits permeability.

To make the right design decision, manufacturers must carefully balance these two factors based on the sheet’s intended purpose—whether it’s a perforated safety grating used for anti-slip platforms or a carbon steel perforated metal sheet for machinery protection.

Formula for Calculating Open Area of Rectangular Perforated Metal Sheets

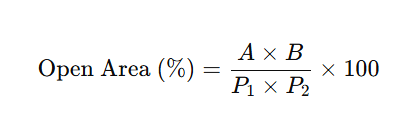

When dealing with rectangular perforations, the open area can be calculated using a simple formula:

Where:

- A = length of each rectangular hole (mm)

- B = width of each rectangular hole (mm)

- P₁ = horizontal pitch (center-to-center spacing in the x-direction, mm)

- P₂ = vertical pitch (center-to-center spacing in the y-direction, mm)

Example:

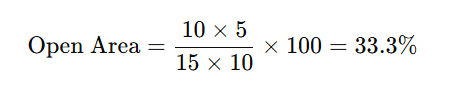

If a rectangular perforation measures 10 mm × 5 mm, and the pitch distances are 15 mm (horizontal) and 10 mm (vertical), then:

This means approximately one-third of the sheet surface allows airflow or light to pass through.

Factors Affecting Open Area Accuracy

- Hole Shape Precision:

Slight deviations in punching or laser cutting can significantly affect the open area ratio. - Material Thickness:

Thicker sheets (e.g., galvanized perforated metal sheets) may have less effective open area due to edge deformation. - Margin and Edge Design:

The unperforated borders around the edges should be excluded from the open area calculation if they are part of the product design. - Sheet Expansion or Flattening:

During post-processing, especially for stainless steel perforated metal sheets, material expansion can alter the hole geometry slightly.

Industrial Applications of Rectangular Perforated Metal Sheets

Rectangular perforations are highly valued across a wide range of industries:

- Agriculture: Used in grain dryers and seed sorting machines.

- Mining: Common in screens and protective guards.

- Construction: Applied in ventilation covers and safety barriers.

- Automotive: Integrated into engine soundproofing panels and filtration systems.

- Machinery Manufacturing: Employed in exhaust and air intake systems.

When a project demands custom airflow or pressure requirements, our factory provides custom perforation design services—allowing users to specify hole size, spacing, thickness, and material type.

Why Choose Our Factory for Your Perforated Metal Sheet Needs

Unlike most overseas suppliers, our Chinese factory specializes in fully customizable perforated metal sheets. We can produce rectangular, round, slot, hexagonal, or micro perforations in various materials, including:

- Carbon steel

- Galvanized steel

- High manganese steel

- Aluminum

- Stainless steel

From one-off prototypes to large-scale production, we ensure consistency, precision, and high-quality finishing. Each rectangular perforated metal sheet can be tailored to your specifications, including open area percentage, material thickness, and sheet dimensions.

If your application requires other configurations, such as a round hole perforated metal sheet for uniform airflow or a micro perforated sheet for fine filtration, we can deliver both standard and customized solutions.

Conclusion

Accurately calculating the open area of a rectangular perforated metal sheet is essential for ensuring optimal performance in industrial applications. Whether you’re designing ventilation systems, machine guards, or filtration components, understanding the relationship between hole size, pitch, and material thickness allows for better engineering outcomes.

Our factory combines years of experience, advanced manufacturing technology, and flexible customization to help global clients get the best solution for their projects.

📧 Contact us: info@perfsheet.com