Introduction

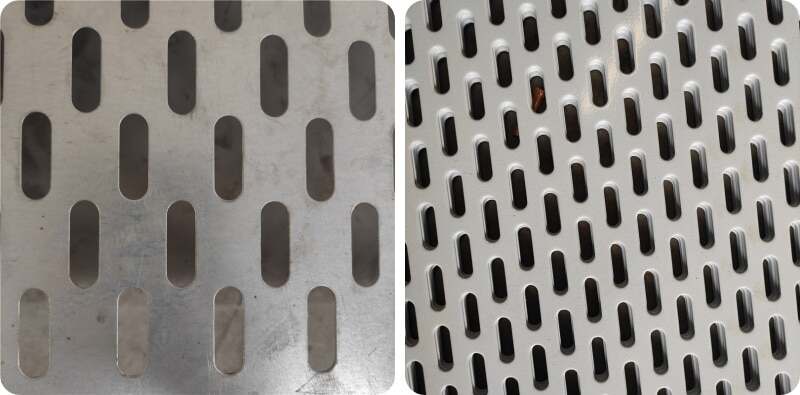

Among the many types of customized perforated metal sheets from China offered by Anping Senchi Metal Wire Mesh Products Co., Ltd., the slot hole perforated metal sheet stands out for its unique design and practical versatility.

This type of perforated sheet features elongated openings that provide excellent ventilation, drainage, and filtration, while maintaining structural strength. It is widely used in architectural decoration, noise control, mechanical protection, and industrial filtration.

1. Structural Design and Material Selection

The structure of a slot hole perforated metal sheet is defined by its narrow, elongated holes, which can be arranged in straight or staggered patterns. The slot shapes may vary in width, length, and orientation to meet specific performance demands.

Depending on the application environment, different metals can be used:

- Carbon steel for strong and cost-effective performance (Carbon Steel Perforated Metal Sheet)

- Stainless steel for corrosion resistance and durability (Stainless Steel Perforated Metal Sheet)

- Aluminum for lightweight and decorative projects (Aluminum Perforated Metal Sheet)

- Galvanized steel for outdoor environments with high humidity

The material selection plays a crucial role in determining load capacity, longevity, and visual appeal.

2. Manufacturing Process

Producing a high-quality slot hole perforated metal sheet involves precise punching or CNC perforation, followed by leveling, cutting, and optional surface finishing (galvanizing, anodizing, or powder coating).

The process allows accurate control over:

- Hole size and spacing

- Open area percentage

- Sheet thickness

- Edge finishing and flattening

Thanks to advanced production equipment, Anping Senchi Metal Wire Mesh Products Co., Ltd. can provide custom perforation patterns and tailor-made designs, whether for a single piece or bulk production.

3. Functional Advantages

The elongated slot design offers several performance benefits compared with traditional round or square holes:

- Excellent Ventilation and Drainage:

The linear openings enhance air and fluid flow, making them ideal for ventilation covers and drainage systems. - Superior Filtration:

The consistent gap between slots ensures uniform filtration, widely used in mining, food processing, and oil industries. - Structural Strength:

The metal sheet retains high load-bearing capacity, suitable for protective guards and mechanical components. - Modern Aesthetic Appeal:

In architectural applications, slot patterns create a sleek, minimalist appearance favored by designers.

For comparison, Round Hole Perforated Metal Sheet offers balanced strength and openness, while Perforated Safety Grating provides enhanced anti-slip properties — both complementing slot hole sheets in specific uses.

4. Applications Across Industries

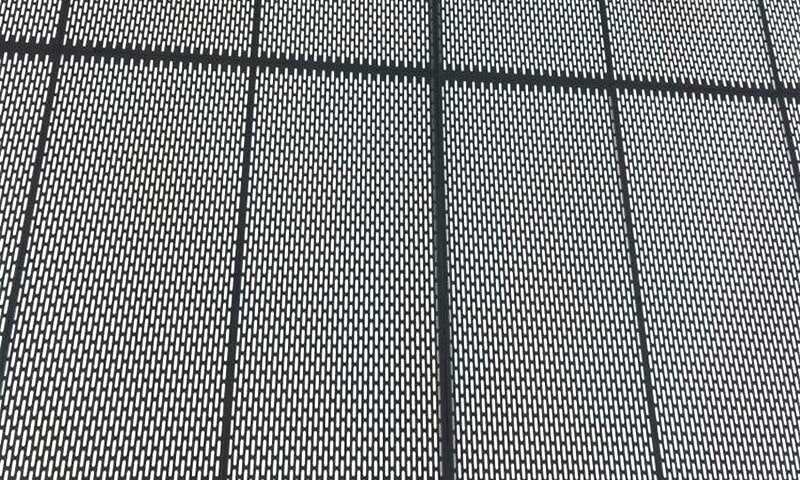

Slot hole perforated metal sheets are used in a wide range of industries due to their balance between strength and permeability. Common applications include:

- Architectural façades and ceilings

- Acoustic and ventilation panels

- Filter screens and sieves

- Machinery guards and protective covers

- Agricultural and mining equipment

- Transportation and automotive components

Their ability to be custom-cut, folded, and coated makes them adaptable for both functional and decorative purposes in modern design.

5. Customization Options

One of the major advantages of working with a Chinese factory like Senchi Metal Wire Mesh Products Co., Ltd. is the flexibility in customization. Customers can specify:

- Hole size, pattern, and orientation

- Sheet thickness and dimensions

- Material type (carbon steel, stainless steel, aluminum, etc.)

- Surface finish and color coating

- Open area ratio (to adjust ventilation or filtration levels)

This full customization service ensures clients receive exactly what their projects demand — from small prototype orders to large industrial batches.

Conclusion

The slot hole perforated metal sheet represents an ideal balance of strength, design, and functionality. Whether used in industrial machinery or architectural aesthetics, it delivers consistent performance and modern appeal.

At Anping Senchi Metal Wire Mesh Products Co., Ltd., we specialize in customized perforated metal sheets tailored to global standards. With years of manufacturing experience and a commitment to precision, we provide reliable products and flexible service to clients worldwide.

Contact us today at 📧 info@perfsheet.com to discuss your custom perforated metal sheet requirements — from material selection to production and shipping.