Why procurement teams choose a specification-first approach

As an industrial metals engineer and B2B sourcing specialist with 20 years’ experience, I’ve seen the same procurement problems repeat: vague RFQs, inaccurate quotes, wrong tolerances, and shipments that don’t fit the assembly line. The fastest way to get accurate pricing and a dependable lead time for Custom Round Hole Punched Panels is to provide clear, engineer-level specifications up front. This guide walks purchasing managers through the exact items manufacturers need — minimizing back-and-forth and lowering total landed cost.

Round Hole Perforated Metal Sheets

Custom perforated metal sheets with precise hole patterns in various materials: stainless steel, aluminum, galvanized steel, carbon steel, copper, brass, and plastic. Durable and corrosion-resistant.

Perfect for architectural screens, machinery guards, acoustic panels, and decorative elements. Factory-direct pricing with cutting/bending services. Request quote or sample today.

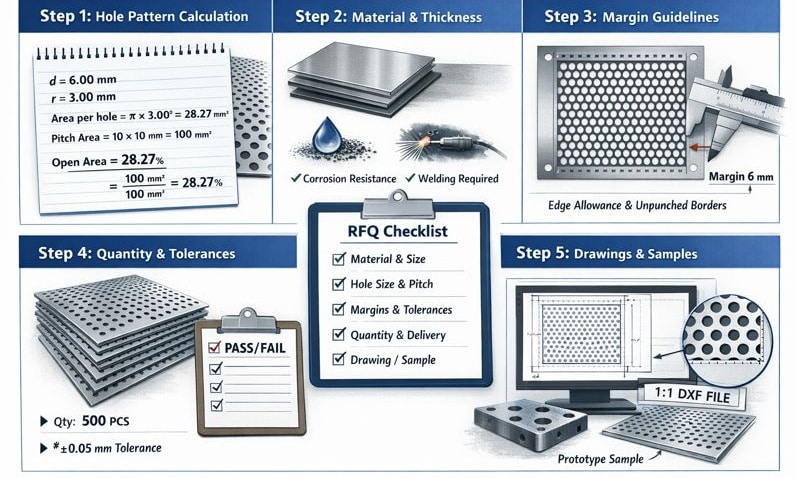

Step 1 — Define the critical geometry: hole diameter, pitch, and pattern

Hole diameter (what to provide)

- Give the nominal hole diameter and the required tolerance (for example: 6.00 mm ±0.05 mm).

- State if holes are deburred or if a particular edge finish is required.

Pitch and pattern (square vs. staggered)

- Provide center-to-center pitch (e.g., 10.00 mm).

- Specify whether the layout is square (rows/columns aligned) or staggered/hexagonal (higher open area for same pitch).

- If you need a specific open-area percentage for ventilation or acoustic performance, say so — manufacturers will select pitch/pattern combinations to hit that target.

Example: how open area is calculated (transparent math for quoting)

If you request an open area target it helps to show the vendor one reference calculation. For a round hole, square pitch:

- Hole diameter d=6.00d = 6.00d=6.00 mm → radius r=d/2=3.00r = d/2 = 3.00r=d/2=3.00 mm.

- Area per hole =π×r2=π×3.002= \pi \times r^2 = \pi \times 3.00^2=π×r2=π×3.002.

- Step: 3.002=9.003.00^2 = 9.003.002=9.00.

- Step: π×9.00=3.14159265×9.00=28.27433385\pi \times 9.00 = 3.14159265 \times 9.00 = 28.27433385π×9.00=3.14159265×9.00=28.27433385 mm².

- Pitch area (square) =10.00×10.00=100.00= 10.00 \times 10.00 = 100.00=10.00×10.00=100.00 mm².

- Open area =28.27433385/100.00=0.2827433385= 28.27433385 / 100.00 = 0.2827433385=28.27433385/100.00=0.2827433385 → 28.27% open area.

Providing one worked example like this saves time and reduces guesswork.

Step 2 — Material, thickness, and mechanical constraints

Material selection

- Specify alloy/grade (e.g., 304 stainless steel, cold-rolled carbon steel, aluminum 5052).

- Call out environmental drivers (corrosive environment, marine exposure, food contact) so the vendor can recommend the right grade and finish.

Thickness and bending considerations

- Provide finished thickness and any forming/bending requirements. Punching and forming interact: thicker gauges may need secondary handling or different tooling.

- If panels will be welded or painted after punching, specify those downstream processes.

Step 3 — Margins, edge allowances, and usable area

Recommended margin guidance

- Vendors need a clear margin (unpierced edge) to mount the panel and prevent tear-out during forming. A pragmatic rule: leave a minimum unpunched margin equal to the greater of (A) twice the material thickness or (B) 3–5 mm, depending on gauge and hole size. State your absolute minimum requirement in the RFQ.

- If you require full-edge perforation to the edge, note any downstream trimming or secondary operations.

Step 4 — Quantity, tolerances, and acceptance criteria

- State order quantity (total pieces and batch sizes). Many vendors price lower at higher volumes because tooling and die wear scale.

- Give dimensional tolerances, acceptable burr size, and whether sampling is acceptable (e.g., 1st-article inspection + lot sampling).

- Include pass/fail criteria (e.g., “no more than 1% holes out of tolerance per panel”).

Step 5 — Drawings, files, and sample requests

- Provide a clear mechanical drawing (2D DXF preferred), material spec, and finish instructions. If possible, attach a 1:1 PDF with a hole-pattern detail and coordinate origin.

- Reserve a line item for a physical sample/prototype if the part is precision critical.

RFQ checklist — what to include (use this as copy-paste into emails)

- Part name / internal part number

- Material and grade (e.g., 304 SS, 1.2 mm)

- Finished dimensions (length × width × thickness)

- Hole diameter and tolerance (e.g., Ø6.00 mm ±0.1 mm)

- Pitch pattern and center-to-center (e.g., square pitch, 10.00 mm)

- Edge margin (minimum unperforated margin)

- Finish requirements (deburr, passivate, paint, zinc coat)

- Quantity and required delivery schedule

- Drawing/DXF/PDF attached and any PMI notes

- Inspection requirements (FAI, Cpk, sampling)

- Packing and shipping requirements, incoterm (EXW, FOB, DDP)

Cost drivers — what affects price and lead time

- Hole size vs. material thickness: very small holes in thick plate may require special tooling and increase cost.

- Open area and pattern complexity: very high open area reduces sheet strength and can add handling cost.

- Secondary operations (forming, welding, coating) add time and cost — list them separately.

- Sample/prototype runs and tight tolerances increase lead time and one-time tooling expenses.

Quality assurance and on-site testing suggestions

- Ask for material certificates (e.g., EN 10204 2.1/3.1) when alloy traceability is required.

- Request a first-article inspection report with measured hole size, pitch, and flatness data.

- For large volume orders, define an agreed sampling plan (e.g., ANSI/ASQ Z1.4 or equivalent).

Logistics, packaging, and installation notes

- Specify how panels should be packed to avoid abrasion or deformation (e.g., layered with protective film, wooden crates for export).

- Provide the mounting detail if panels are part of an assembly — vendors can add finishing operations like tapped holes or punched tabs to match your fixtures.