Galvanized perforated metal sheets are widely used in architecture, industrial filtration, HVAC, and outdoor fixtures because of their strength and corrosion resistance. But a good zinc coating only performs if it is applied correctly and verified with the right inspection methods. This article walks buyers, specifiers, and QC teams through practical inspection techniques, relevant international standards, and acceptance tips specifically tailored for perforated sheets.

Galvanized Perforated Metal Sheets

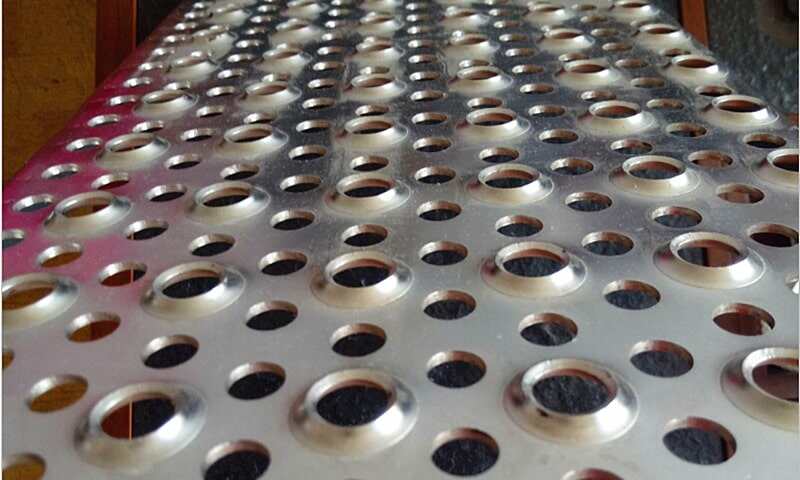

Galvanized perforated metal sheets are coated for enhanced corrosion resistance, making them ideal for outdoor and industrial environments that require durability and longevity.

Why inspection matters for perforated sheets

Perforated sheets have a high surface-to-edge ratio and many perforation edges where coating thickness and adhesion can vary more than on flat panels. Uneven thickness at hole edges, thin deposits inside small apertures, or poor adhesion at punched edges can shorten service life—so inspection isn’t optional for critical projects. For reliable results, combine simple visual checks with quantitative, instrument-based measurements.

Core inspection methods (how to check a zinc coating)

1. Visual inspection — first, fast, and essential

Start with a trained visual inspection under good light: look for uniform color, excessive spangle or bare spots, runs or drips, and white rust (zinc corrosion) or red rust (underlying steel). For perforated sheets pay special attention to the perforation edges, countersinks, and any welds or cut edges. Visual assessment is quick but subjective; use it to decide where to take instrument measurements.

2. Coating thickness — non-destructive gauges

Non-destructive thickness gauges are the industry standard for routine checks. Two widely used physical principles are:

- Magnetic induction (magnetic gauges) for non-magnetic coatings (zinc) on ferrous bases; this is covered by international practice and standards for magnetic measurement. These handheld gauges give fast readings and are ideal for spot checks across a perforated sheet.

- Eddy-current methods for coatings on non-ferrous substrates (less common for galvanized steel but useful for certain alloys).

Common industry documents and guidance on which instruments and procedures to use include ASTM and ISO practices; use them to set sampling frequency and instrument calibration schedules.

3. Destructive or lab methods (when you need detailed structure)

For precise layer structure, metallographic cross-sections under optical microscopy or SEM can show coating morphology (zinc-iron intermetallics, diffusion layers) and measure thickness at the microstructural level. Use lab methods when acceptance is critical, when disputes arise, or when perforation edges need detailed analysis.

4. Gravimetric and weight-gain checks (batch verification)

For batches of perforated sheet produced continuously, some factories rely on weight-gain calculations (coating weight per area) as a complementary check. This approach estimates average coating mass and is most useful for process control rather than spot inspections.

Relevant standards to reference (short list)

To specify acceptance or inspection procedures in purchase orders or QC plans, reference recognized standards rather than ad-hoc rules. Key standards include:

- ASTM A123 / A123M — general requirements for hot-dip galvanized coatings on iron and steel products.

- ISO 1461 — hot-dip galvanized coatings on fabricated iron and steel — specifications and test methods.

- ISO 2178 (magnetic method) and ASTM D7091 / ASTM E376 / ASTM B499 — accepted practices for nondestructive coating thickness measurement using magnetic and eddy-current gauges.

- ASTM B117 (salt spray) and related corrosion tests — used to evaluate relative corrosion resistance in accelerated conditions (note: salt spray results are comparative, not perfect predictors of field life).

- ASTM A780 — accepted practice for repair of damaged or uncoated areas of hot-dip galvanized coatings.

Refer to the specific clause in each standard for sampling plans, minimum coating thickness/weight values, and allowable surface conditions. For perforated products, many specifications call for extra attention to coating continuity at holes and punched edges.

Practical inspection plan for perforated galvanized sheets (step-by-step)

- Acceptance sampling plan

- Agree contractually on sampling frequency and acceptance limits (e.g., one reading per X sq. ft. or one reading at each lot). For small orders, 100% visual + spot thickness checks; for large batches, statistically based sampling per ASTM/ISO guidance.

- Visual pass/fail criteria

- No bare steel visible, no excessive runs, no adherent scale; localized white rust may be acceptable depending on spec — record and photograph any anomalies.

- Thickness measurements

- Use calibrated magnetic thickness gauges (ISO 2178 / ASTM D7091 guidance). Measure at multiple points: flat field, near punched hole centers, and on the punched edge. Record min/max/average and compare with the specified minimum thickness or coating weight.

- Edge and aperture checks

- Small apertures and slug edges often get thinner coats. If holes are small (<3 mm) or many, add extra checks inside apertures or specify a minimum thickness at edges in the contract. Use microscopy for dispute resolution.

- Corrosion testing (if required)

- For engineered or marine applications, require salt-spray (ASTM B117) or cyclic corrosion testing; ensure the test method and exposure hours are agreed in advance because results depend heavily on test protocol.

- Repair and acceptance of damaged areas

- If bare spots or damage are found, follow ASTM A780 methods (zinc-rich paint, zinc solder, or metallizing) and re-measure thickness in repaired zones. Agree limits for repair area size and method before acceptance.

Common pitfalls and how to avoid them

- Assuming flat-panel standards apply without adjustment. Perforated sheets behave differently—specify extra edge/inside-hole checks.

- Poor sampling plans. Too few measurements miss local thin spots; use a mix of visual and instrument sampling.

- Uncalibrated equipment or untrained operators. Measurement accuracy depends on calibration, probe selection, and technique — document calibration dates and operator training.

- Over-reliance on salt spray alone. Salt spray is useful for comparative testing but not a guaranteed field-life predictor; use it alongside real-world exposure data when possible.

Final checks before shipment

- Confirm instrument calibration certificates and attach measurement logs.

- Photo record of representative panels (include hole-edge closeups).

- Confirm any required repair work and the method used.

- Issue an inspection report with min/max/mean coating thickness and sampling map.

Summary (quick takeaways)

- Use a combined approach: visual inspection + magnetic/eddy-current thickness checks + lab analysis when needed.

- Reference internationally recognized standards in contracts (ASTM A123, ISO 1461, ISO 2178, ASTM D7091, ASTM B117, ASTM A780).

- For perforated sheets, add targeted checks at hole edges and inside apertures — these are the usual weak spots.

Ready to inspect or specify tests?

If you’d like a simple inspection checklist or an editable PO clause tailored to your perforated sheet size, hole pattern, and environment (indoor vs. coastal), I can draft one for you. To move forward, email your technical specs (material, thickness, hole size, intended service environment) to info@perfsheet.com — use that address for quotes, inspection plans, or sample orders.

References & further reading (selected): ASTM A123/A123M; ISO 1461; ISO 2178; ASTM D7091; ASTM B117; ASTM A780; American Galvanizers Association technical notes.